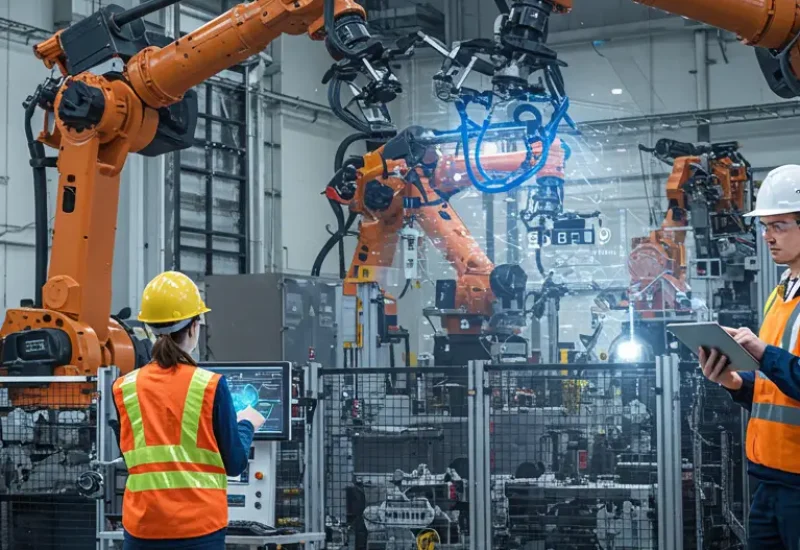

Engineering innovation. Empowering industries. Building the future.

At NeutroV, we are committed to redefining engineering technology through innovation and excellence. Established in 2021, our company consistently delivering cutting-edge solutions that enhance efficiency and drive progress across multiple sectors.

Our expertise spans various engineering disciplines, where we have successfully executed projects that showcase our technical prowess and dedication to high standards.

Our journey continues, fueled by a passion for innovation and a commitment to excellence. We are ready to take on new challenges, explore emerging technologies, and lead the way in engineering advancements that make a difference.

Business Benefits

Key Features

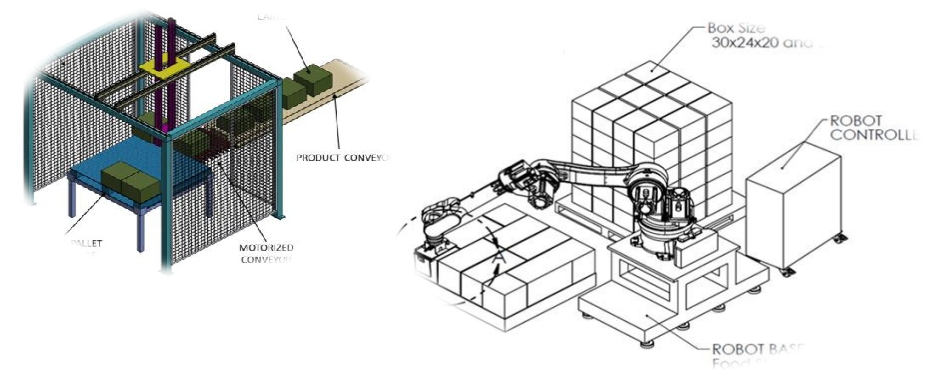

Supporting quick, efficient order fulfilment, conveyors are versatile tools that move, separate, and support automated operations. Conveyor systems are modular, can handle a variety of product sizes, shapes and weight, and can be tailored to operate in a variety of facility layouts. Conveyor technologies generally fall into three classifications -sortation, accumulation and transport.

Conveyor System Benefits

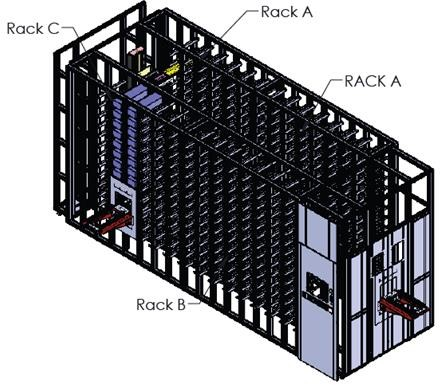

Mini Load AS/RS Features

Radioshuttle System

Benefits of Automated Palletizing

Palletizing Options

System Process

Specifications

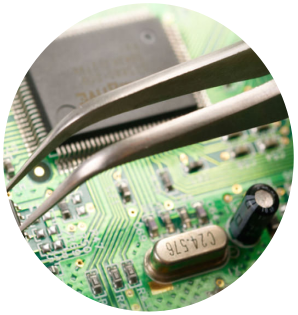

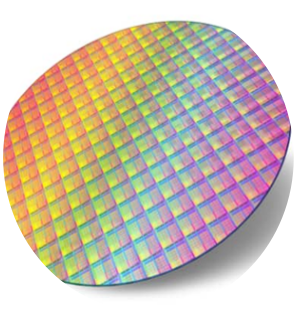

Capture high-quality images using 2D, 3D, thermal, or hyperspectral cameras for inspection and monitoring.

Proper lighting, such as LEDs and ring lights, ensures clear images by reducing shadows and glare.

AI-driven software detects defects, sorts products, and automates decisions for better accuracy.

Fast and reliable data transfer allows seamless communication between vision systems and automation tools.

Vision systems work with PLCs, HMIs, and SCADA to improve process control and efficiency

Use to product transferring, packing, sealing and barcode labelling.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

© NEUTROV TECHNOLOGY SDN. BHD. | 202101029931 (1430231-D) | ALL RIGHTS RESERVED.

Allright Reserved – Lapak Hand Watch