Use to product transferring, packing, sealing and barcode labelling.

Key Features

Business Benefits

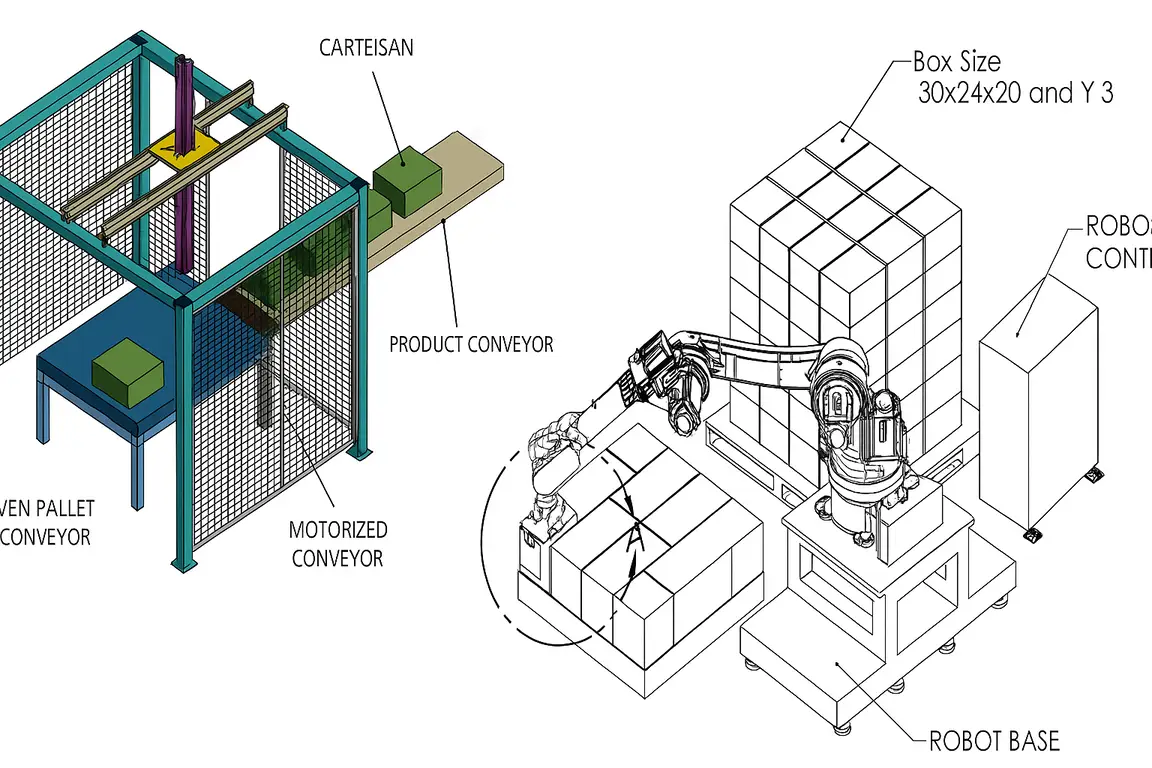

Supporting quick, efficient order fulfilment, conveyors are versatile tools that move, separate, and support automated operations. Conveyor systems are modular, can handle a variety of product sizes, shapes and weight, and can be tailored to operate in a variety of facility layouts. Conveyor technologies generally fall into three classifications -sortation, accumulation and transport.

Conveyor System Benefits

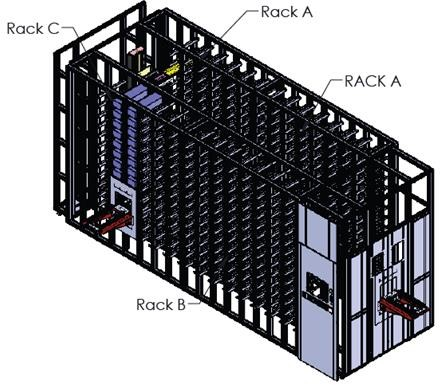

Mini Load AS/RS Features

Features & Benefits:

Smart Pallet Strapping Machine:

Benefits of Automated Palletizing

Palletizing Options

System Process

Specifications

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

© NEUTROV TECHNOLOGY SDN. BHD. | 202101029931 (1430231-D) | ALL RIGHTS RESERVED.

Allright Reserved – Lapak Hand Watch